Whether you are a corporate, educational institute, a professional or student we always have the right solution customised for you.

Our Product

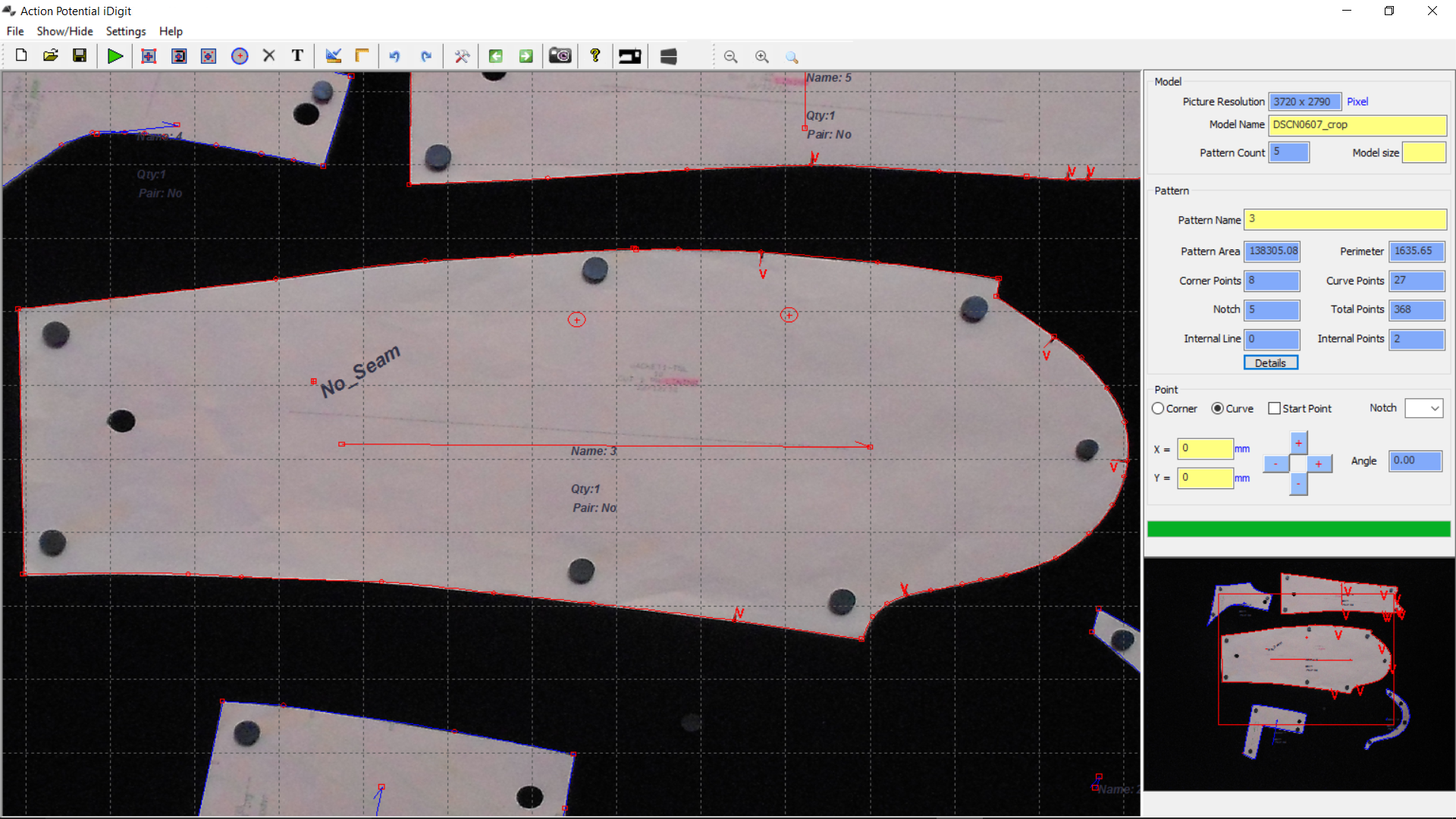

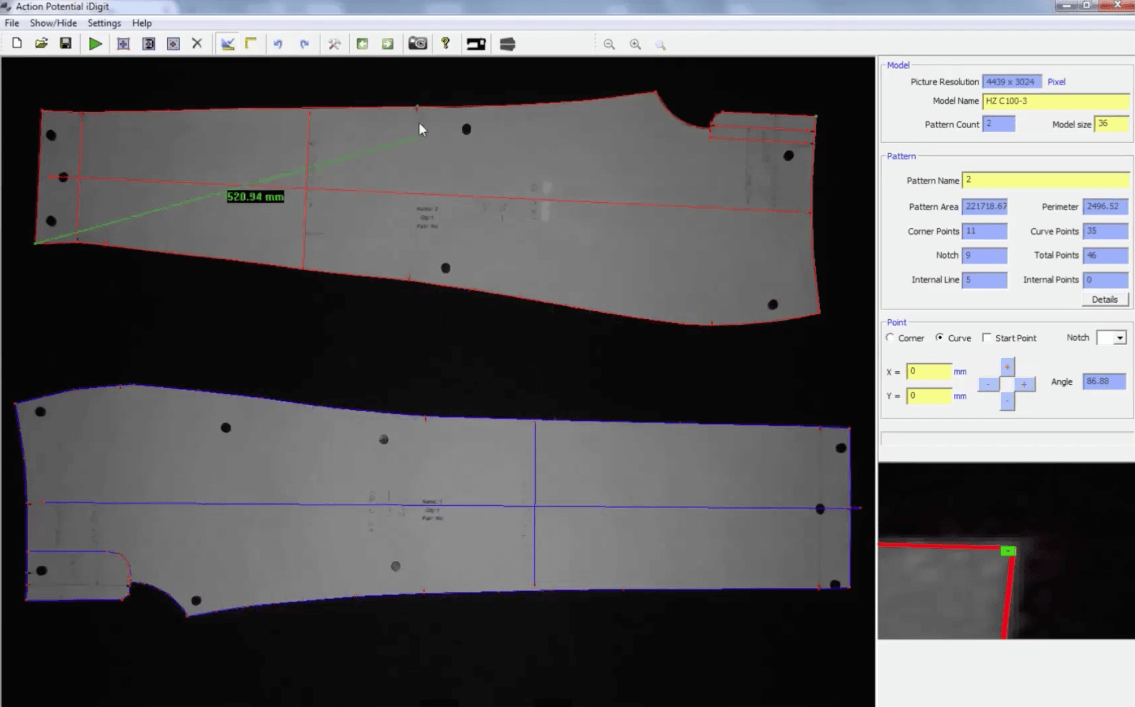

Everything you need to know about iDigitPattern Digitising

Pattern digitising is scanning patterns into a CAD/CAM system. This is the first step in mass producing many items, including garments, furniture, leather goods, automotive parts, metal or composite sheets and many more. This process traditionally required a table digitiser. Today, photo digitising is becoming more popular due to advantages like high speed and accuracy whilst requiring less work space and training.

Why iDigit is Different?

iDigit allows professional quality digitisation and processing at a fraction of the cost of traditional systems whilst requiring almost no training or maintenance budget! Photo digitisation allows for superior measurement precision and the capture of details like notches and grain lines. Better still, because the tedious process of calibration has been completely removed, it is less prone to error even after being moved repeatedly. Not only does this compact, portable camera-based system give you back several square meters of precious floor space, it gives you back a much more precious commodity – your time!

Mind the calibration!

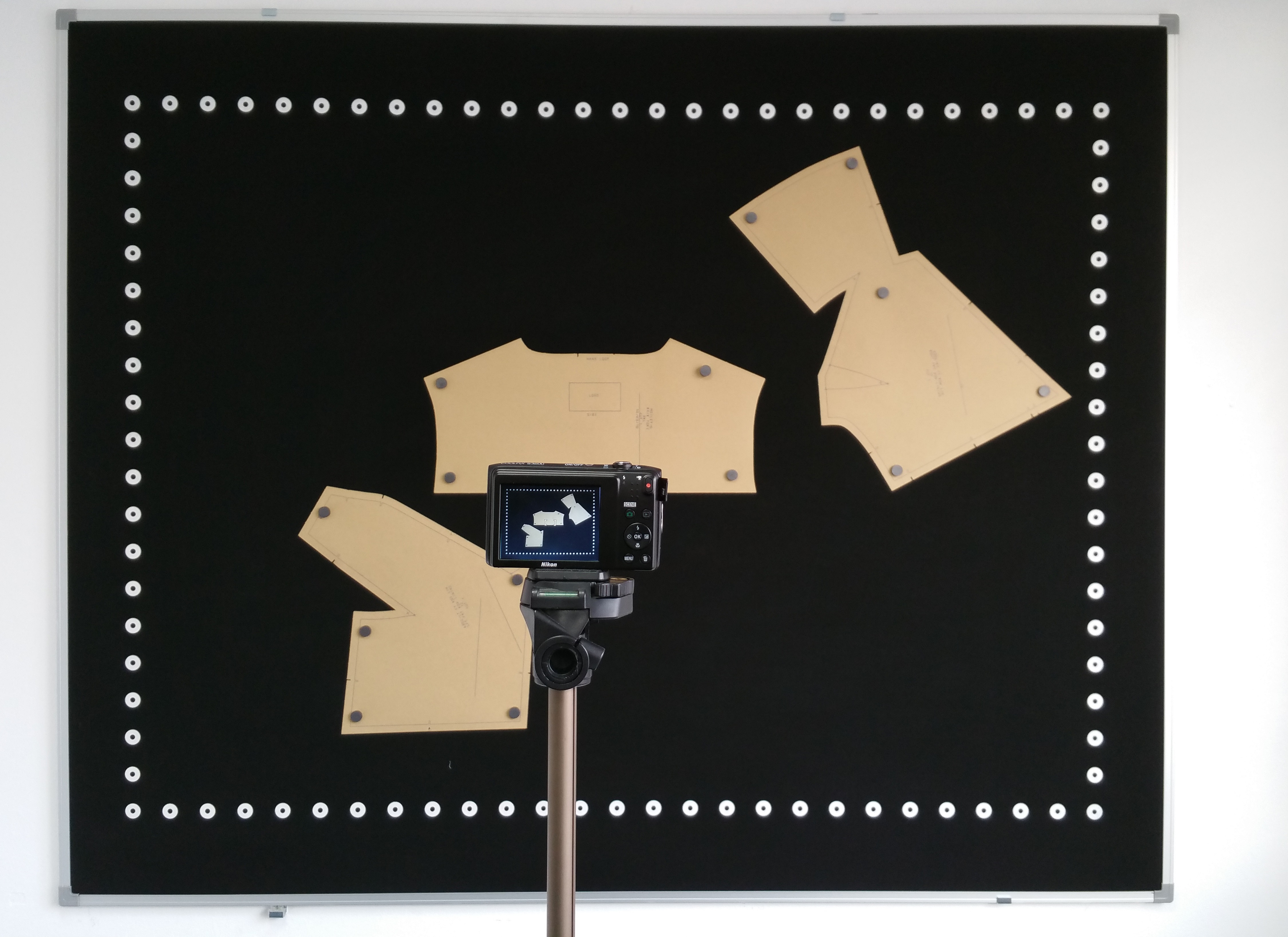

iDigit’s most significant advantage over competing systems is that it does not require calibration. Calibration is a difficult and tedious process, and if either the table or the camera moves from its original location most systems will have to be re-calibrated before they can be used.

Worse, improper calibration call lead to erroneous manufacturing. Best to remove that step altogether! iDigit can tether a camera for automatic shooting with the press of a single button, and can even automatically extract the last picture taken and process it. iDigit offers a larger digitising area which allows you to digitise larger patterns than in any other photo digitising systems.

How iDigit Saves You Time?

Laying out the patterns alone typically takes several minutes with table digitisers, and involves adhesive tape which is time consuming to stick and remove. Manual digitising records only one point at a time and takes even longer. Also most photo digitisers require calibration which takes a considerable amount of time and causes disruptions.

iDigit overcomes all those shortcomings thanks to its self-calibrating magnetic board. This unique board allows for affixing/removing the patterns on the surface using magnets and produces consistent results each time even from different angles, eliminating manual calibration. This means you can start using iDigit right away and without any calibration related downtime. iDigit digitises all patterns placed on its magnetic board in mere seconds, regardless of their number, colour or complexity.

Installation & Training

Once the system is received we assist you with installation and get you ready to start benefiting iDigit’s advantages with remote support. Training is also done remotely which typically takes an hour.