Thank you for showing interest in our pattern digitising system, iDigit.

As you are about to make an important decision on investing on a new technology that will have a significant effect on efficiency of your business, it is worth putting some crucial aspects of digitising technologies under the spot light.

Although various photo digitising systems available in the market might seem more or less similar, the difference lies in details which greatly affects your digitising experience. We believe that the ultimate photo digitiser should provide the fastest possible digitising experience that doesn’t cost a fortune, without compromising accuracy.

Therefore, we encourage customers scrutinising their options taking into consideration the following aspects that are crucial:

1- CAPABILITIES

The ideal digitiser must be able to cope with all tricky cases presented by variety of patterns:

1.1 Colour: A good photo digitiser is supposed to digitise all sorts of colours as well as patterns drawn on transparent film.

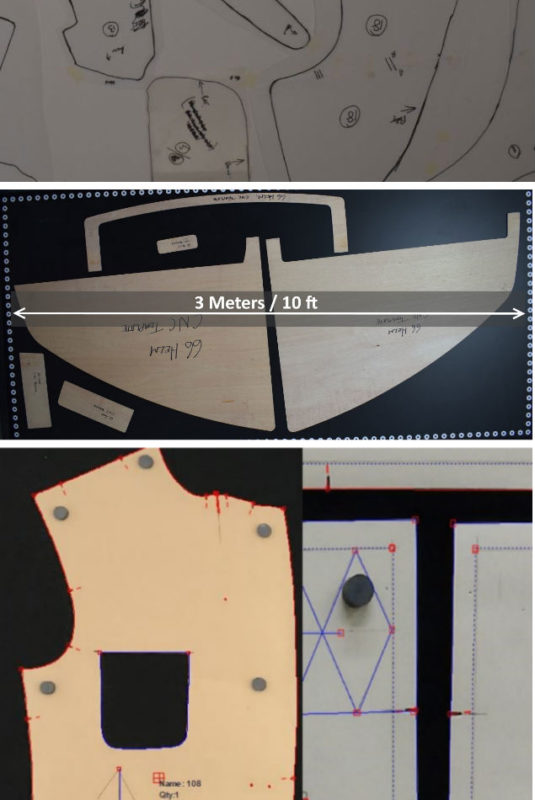

1.2 Material: You should be able to digitise any material such as paper, card, plastic, plywood, fabric, fiberglass, calico, canvas, leather, metal, felt etc.

1.3 Thickness: If you have thick material such as plywood it presents a challenge to most photo digitisers due to the complications the thickness presents to the system. The ideal photo digitiser must allow you specify your material thickness to get around this by itself.

1.4 Worn out patterns: It’s straightforward to digitise neat, brand new patterns. But what about those which’ve seen better days? In order to digitise old, worn out and damaged patterns without having to spend too much time on correcting them your photo digitiser must have automatic smoothing functions.

1.5 Traced patterns: Some patterns aren’t cut to the shape but rather drawn or sketched onto a sheet of material. You’d expect from a good digitiser to pick those drawings up if they are thick enough, also to allow you draw them yourself if need be.

1.6 Large format patterns: Not many photo digitisers today might be able to offer the digitising area with the size you require, without compromising accuracy. If your patterns are very large and you have the space for it then your digitiser should be able to offer a customised digitising surface.

1.7 High accuracy patterns: If your patterns require high precision can your photo digitiser offer that?

1.8 Automatic feature detection: Most photo digitisers will detect the pattern outline. But what about notches, internal lines, grain line, seam allowance, drill holes and cut-outs? These features must be detected by the software automatically.

2- EASE OF USE

2.1 Calibration: We recommend keeping away from systems that require calibration. It is tedious, time consuming and makes the system prone to errors. Self-calibrating systems should be preferred.

2.2 Robustness (working in any environment): Let’s say you relocated your photo digitiser. The surface-camera distance and angle changed, light conditions are different etc. Will it still work without having to call in technical support

2.3 Installation and training: We think the ideal photo digitiser must be instant, plug & play style system. Both installation and learning should be quick and easy which allows the users start utilising it from day one.

3- COSTS

3.1 Maintenance costs: It’s not about only the initial investment you make to purchase the system. Ideally, you’d like to spend as little as possible over time for support, upgrades and maintenance.

4- GUARANTEE & REFUND

Despite the reputation, verbal assurances or references you might be given, nothing gives the peace of mind like an official guarantee & refund policy. After all, no one wants to end up with a product that doesn’t work for them.

Copyright © 2018 Action Potential Tech Ltd. All rights reserved.